Accurate measurement is key in several industries nowadays. There are objectives of weighing systems in different sectors. Its role can be objective, and it has become crucial in ensuring accuracy. The load cell is one of the basic elements in these systems.

Controlling multiple load cells makes things easy for complex weighing systems, but to harness the optimal performance from your load cell control solution, you need to understand the technologies available.

Understanding Load Cells

Load cells are sensors that convert the force exerted on them (tension, compression, or shear) into an electrical signal. This change enables real weight representation. They are essential in manufacturing, logistics, agriculture, and other fields. Load cells include several types and are designed for different applications. The hydraulic, pneumatic, and strain gauge load cells are just a few to mention.

One of the most widely used types is strain gauge load cells, which measure force via electrical resistance. As you apply a load, the strain gauge is deformed, changing shape and thus changing electrical resistance, which is then transformed into a physical output that can be measured.

The Need for Control for Load Cell

Load cell control solutions handle data from load cells. They guarantee the stability and accuracy of measurements. These controls accurately preserve, even in tough surroundings, by reducing the noise and calibration. This is especially essential in places where temperature changes or vibration occurs.

In the absence of control, the data from the load cells could be wrong. This inaccuracy may cause expensive mistakes during production or shipping. Therefore, it is important to adopt reliable control solutions to ensure the desired quality and efficiency.

Elements of a Control System for Load Cell

A load cell control system typically comprises the following elements: These combine to measure, process, and display weight data.

Signal Conditioners

Signal conditioners translate the raw signals from load cells. They are designed to boost low signals and filter noise, guaranteeing that data sent to other system components is healthy and robust.

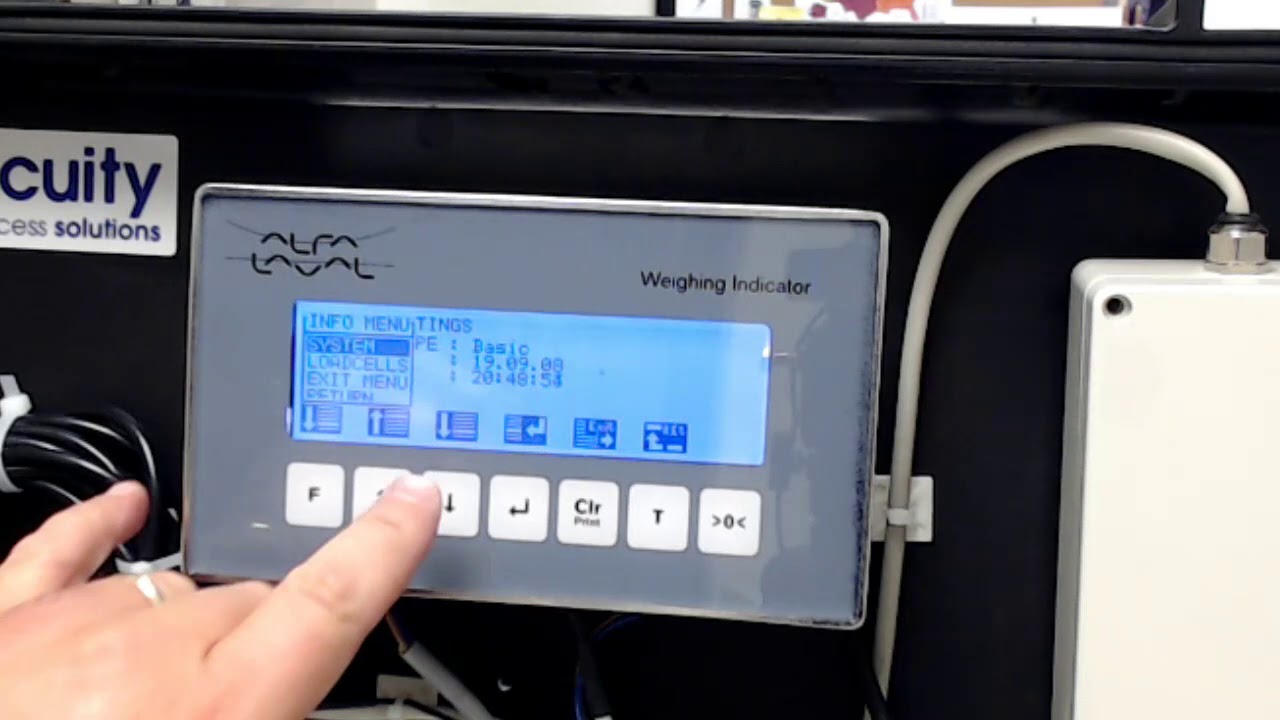

Indicators and Displays

These show the weight that has been measured. They are calibrated in such a manner that they give accurate readings on these devices. They can further provide an extended feature set that includes data logging or interactivity with an external system.

Controllers

Now, controllers are responsible for the entire working of the weighing system. They sense inputs from load cells and perform commands according to pre-programmed instructions. Automation, which means a system can act without human interaction, happens with the use of controllers.

Use Cases Across Different Sectors

Load cell monitoring solutions are used in several sectors. These systems have their unique advantages for each industry.

Manufacturing

Manufacturing needs to hit some precise targets. It ensures that the product is weighed according to specification. This is important, especially in the automotive and aerospace industries, where accuracy is a risk to safety and performance.

Logistics and Warehousing

In logistics, loading and unloading processes are crucial. Load cells for efficient storage and transportation accurately weigh goods. This helps prevent overloading and allows better adherence to regulations.

Agriculture

Load cells are widely applied across agricultural equipment like grain silos and livestock scales. Correct weight data provides perfect feed distribution and inventory monitoring, enhancing productivity and preventing feed waste.

Advancements in Technology

Recently, technological advancements have improved load cell control solutions. Digital integrations enable the monitoring and analysis of data in real time. Wireless communication allows you to access and control things from afar, which makes this system flexible and efficient.

Smart load cells are growing in numbers. These gadgets come with built-in features, including advanced sensors and connectivity. They offer improved data accuracy and provide for predictive maintenance, minimizing downtime and extending system life.

Challenges and Solutions

Even though they have several benefits, load cell systems can have a few issues. Factors such as temperature and humidity in the environment can influence measurements. Manufacturers make load cells with materials and coatings to alleviate these problems.

The other major aspect is calibration. Periodic calibration maintains the accuracy of continual delivery, while automated calibration systems provide convenience and consistency with less human involvement, leading to less human error.

Conclusion

Load cell control solutions provide the right answers for complex weighing systems. They are used to achieve accuracy and reliability in various industry verticals. These systems will further develop as technology evolves to provide even more features. Once one has a good understanding of potential control solutions to consider, the potential efficiency and quality gains from their implementation may be significant. Keeping abreast with such developments can help industries remain competitive and meet the requirements of contemporary production and logistics.